On Demand Machinery

Our most significant achievement is being able to successfully design and manufacture ODM equipment on American soil. It is with great pleasure that we state all ODM equipment is made with pride in U.S.A.

Book Binding Made Simple

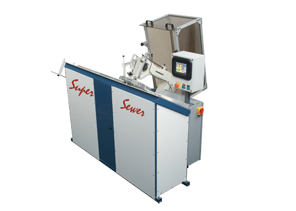

Casemaking System

The Casemaking System which includes: the Spreader, Slider, Stomper and Squeezer. ODM equipment can help you begin to produce your own hard covered books.

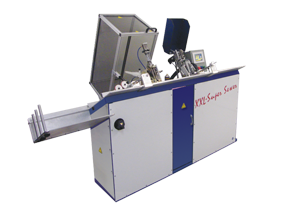

Casemaking XXL System

The Next Generation Casemaking XXL System™ will enable you to produce wallet size (4” x 4”) up to oversize tabloid (22.75” x 46.75”) hard book covers using the same four processes as previously described in the Casemaking System: the Spreader, Slider, Stomper and Squeezer. Built in the USA, ODM machines work seamlessly with both the Sticker™ and Smasher™ XXL Series.

Super Sewer XXL

ODM Super Sewer™ XXL – Ideal for Sewing Books from Wallet (5×5”) to Tabloid (18×18“) Size … up to 1” Thick!

Sticker

The ODM casing machine! No make-ready time is required as the machine is self-adjusting. The glue stations are easily removed for a quick cleanup.

Sticker XXL

ODM Sticker™ XXL is designed for casing-in hard cover books.

Produce wallet size (4” x 4”) to oversize tabloid (18” x18”) hard cover books from 1/32” to 4” thick; 100 to 300 books per hour.

Smasher

The Smasher is a self-adjusting hydraulic building in machine. The operator places the cased-in book into the Smasher and depresses a foot pedal that brings the top joint iron in contact with the book.

Smasher XXL

ODM Smasher™ XXL is designed for forming the joints and pressing (building-in) hard cover books. Produce wallet size (4” x 4”) to oversize tabloid (18” x18”) hard cover books from 1/32” to 4” thick; 100 to 300 books per hour.

Super Sticker

The Super Sticker™ can produce 400 to 600 books per hour.

Automated casing-in machine is designed for high volume, on demand binding operations. No special skills are required to operate this self-adjusting machine.

Book-Trac

ODM has partnered with Productive Solutions (Data Integrity Control Systems) and combined their expertise to expand the Book-Trac™ family of products. Thus creating the ability for customizable automation controls and production reporting capabilities to all of our book-manufacturing clients.

Super Smasher

The Super Smasher™ is a self-adjusting; automatic feed, hydraulic building-in machine. It’s the next generation of the original Super Smasher™.

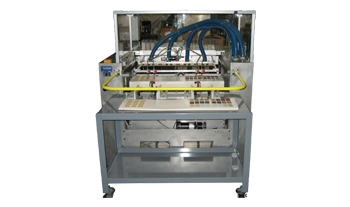

Super Line

Automated Super Line for Super Sticker™ (Casing-in) and Super Smasher™ (Building-in) machines.

Increase your book production while lowering your labor costs. Produce 400-600 ‘library-quality’ hard cover books per hour!

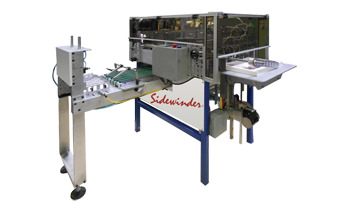

Sidewinder

ODM Sidewinder™ – Ideal for Producing ‘Lay-Flat’ Panoramic Photo Book Blocks up to 1-Inch (25 mm) thick!

The Sidewinder™ is an automated, on-demand bindery system that’s designed for Mohawk’s Panoramic line of i-Tone photo papers.

Separator

The Separator is a simple, safe machine to die cut windows in finished books.

The Separator™ can produce 200 to 400 die cut covers per hour.

Slicer

The ODM Slicer™ is a simple, hand-operated machine designed to cut perfect corners on cover sheets (up to 1” stack height) prior to the casemaking process of producing the hard cover.

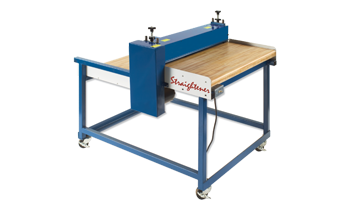

Straightener

Straightener takes warped cover boards, or covers and removes the curl that sometimes occurs during the board manufacturing process and/or, casemaking.

Super Swatcher

The Super Swatcher™ is an automatic swatch machine designed for mounting sample swatches to color cards (sample cards) for the textile industry.

Stenciler

The ODM Stencil Gluing Machine applies a pattern of adhesive or overall coating to photo album pages, envelopes, sample cards, display easels, pressure sensitive box blanks, skin pack cards or any product requiring a precision coating of adhesive in a pattern.

Air Press

Ideal for photo album pages, file folder products featuring an accordion type folder and many hand assembly items that require pressing.